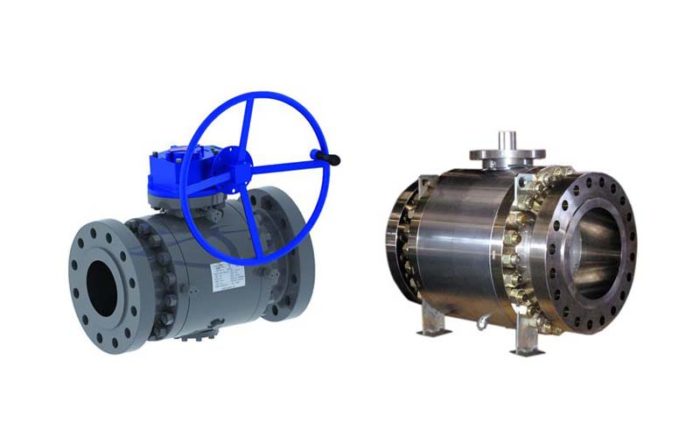

Forged Steel Trunnion Ball Valve

Forged Steel Trunnion Ball Valve is an excellent choice for on/off service in large and high-pressure applications because the ball is fixed at the top and bottom of the design. It is equipped with a sealant injection system for both stems and seats to allow external intervention to prevent seat or stem leakage.

EG Valves have over 15 years of experience, we always strive to keep good quality and competitive prices for all our global valued customers.

If you have a special request regarding Forged Steel Trunnion Ball Valve, please feel free to contact us using the green ENQUIRY button as below.

Product Description

- Body Material: Forged Carbon Steel, Stainless Steel, Alloy Steel, Duplex Steel, etc.

- Bolted Bonnet and Split Body, Fixed Ball inside

- Blow-out Proof Stem and Fire-safe Design

- Low Emission Packing and Anti-Static Design

- Soft Sealing or Hard Sealing as per Customer’s Request

- Full Port or Reduced Port Design

- Size Range: NPS 2” ~ 36” ; DN50 ~ DN900

- Pressure Rating: Class 150 ~ Class 2500 ; PN16 ~ PN420

- End Type: RF, RTJ, BW

- Mode of Operation: Worm Gear, Electric, Pneumatic, etc.

Technical Specifications

- Design and Manufacture: API 608 , API 6D or DIN 3356

- Face to Face Dimensions: ASME B16.10 or DIN 3202

- Flange Ends Dimensions: ASME B16.5 , ASME B16.47 or DIN 2543-2551

- Butt-Welding Ends: ASME B16.25 or DIN EN 12627

- Inspection & Test: API 598 , API 6D or DIN 3230

- Fire-Safe Standard: API 607 , API 6FA

- Top Mounting Pad Standard: ISO 5211

Packaging and Delivery

- Packing Details: Inner: Polybag, Outer: Export Standard Plywood Case

- Production Lead Time: According to the quantity, Normally within 35~40 days

- Transport Method: Seaway or Airway as per Customer’s Request

- CATEGORY Ball Valves

- TAGS